Robotic Ropes - Polyethylene Fiber Rope/Composite Rope

I. Structure:

II. Application:

Ultra-High Strength Polyethylene Fiber Rope: Applications in power transmission,

tendon drive, sensors, and other transmission and auxiliary mechanisms within

robotic dexterous hands, high-precision robotic arms, medical surgical robots, micro

grippers, logistics robots, underwater robots, etc. 1. Advantages: Polyethylene Fiber:

Composite Rope: Combines the characteristics of metal ropes and polymer

materials to achieve high elastic modulus, low elongation, high fatigue resistance,

friction resistance, and creep resistance.

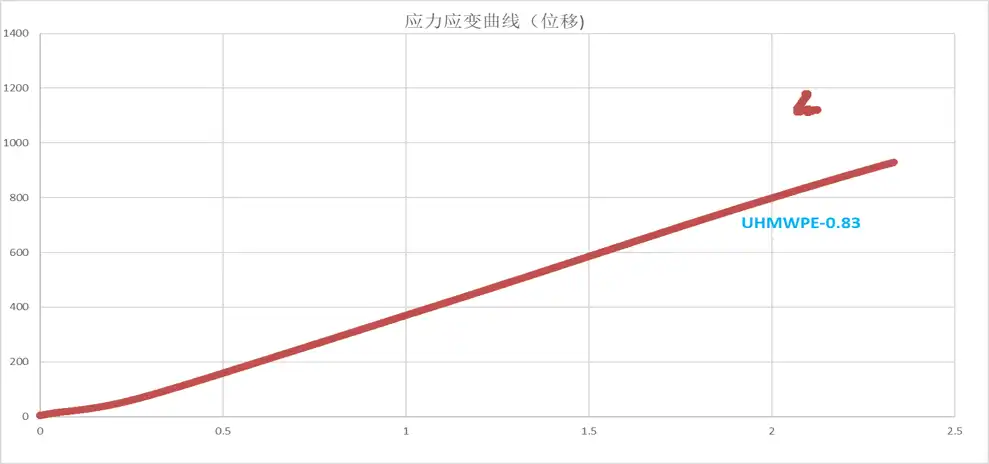

2. Performance Parameters: Benchmark Comparison:  Figure 2: Performance Comparison

Parameter Table:

Table 1: Parameter Table

|

|||||||||||||||