|

PV/Semiconductor/Stone Cutting Ropes

I. Advantages:

- Stainless steel micro ropes successfully break the long-term monopoly of

Japanese wire ropes in the industry, achieving a domestic breakthrough.

- Pioneered the application of tungsten wire material in loop cutting wires

domestically, developing new tungsten wire rope manufacturing processes and

dedicated equipment.

- Excellent fatigue performance, with comprehensive cutting quality leading the

industry. Precise deformation control ensures stable product consistency.

- Precise deformation control, outstanding product consistency and stability,

ensuring higher reliability and durability.

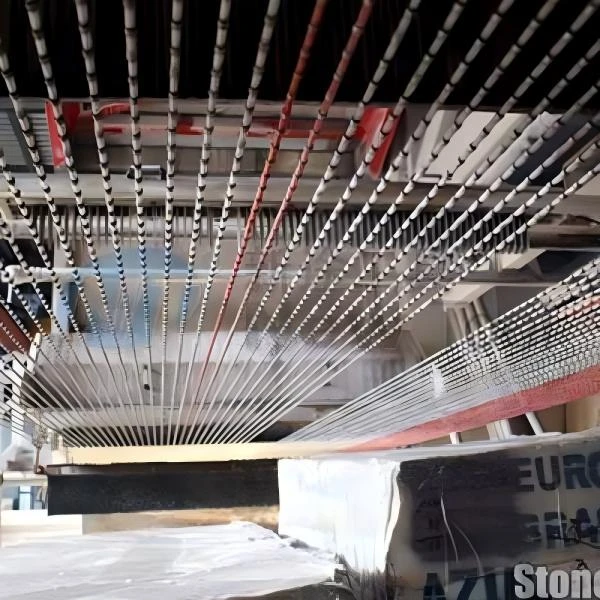

II. Structure:

Figure 1: Structure of PV/Semiconductor/Stone Cutting Ropes

III. Applications:

Applications in industrial processing fields such as stone

quarrying, shaping, slab cutting, mining and quarrying industry, metal cutting,

experimental research, etc.

1. Features:

- Breakthrough in Domestic Production: Successfully broke Japan's long-standing monopoly on DMC steel wire ropes, achieving independent domestic manufacturing

- Process and Equipment Innovation: Pioneered the use of tungsten wire in cutting line saws, developing novel rope-making techniques and specialized production equipment

- Precision Deformation Control: Accurately manages minute rope deformations to ensure product consistency and operational precision

- Consistent and Reliable Quality: Rigorous production processes and comprehensive testing ensure uniform product performance.

- Long-Term Reliability: Maintains high performance over extended use, delivering dependable solutions for customers.

2. Performance Parameters:

Parameter Table:

| Diameter (mm) |

Material |

Structure |

Breaking Strength (N) |

| 0.21 |

Stainless Steel |

1X7 |

≥78 |

| 0.30 |

Stainless Steel |

1X7 |

≥150 |

| 0.33 |

Stainless Steel |

1X7 |

≥158 |

| 0.36 |

Stainless Steel |

1X7 |

≥230 |

| 0.37 |

Stainless Steel |

1X7 |

≥230 |

| 0.45 |

Stainless Steel |

1X7 |

≥300 |

| 0.50 |

Stainless Steel |

1X7 |

≥340 |

| 0.60 |

Stainless Steel |

1X7 |

≥430 |

| 0.70 |

Stainless Steel |

1X7 |

≥630 |

| 1.00 |

Stainless Steel |

7X7 |

≥1100 |

| 1.50 |

Stainless Steel |

7X7 |

≥1300 |

| 1.75 |

Stainless Steel |

7X7 |

≥1700 |

| 1.80 |

Stainless Steel |

7X7 |

≥2800 |

| 2.00 |

Stainless Steel |

7X7 |

≥3200 |

| 3.00 |

Stainless Steel |

7X7 |

≥6500 |

| 3.00 |

Stainless Steel |

7X19 |

≥6500 |

| 3.00 |

Stainless Steel |

7X49 |

≥7200 |

| 1.00 |

Tungsten Wire Rope |

1X7 |

≥1100 |

| 0.51 |

Tungsten Wire Rope |

1X7 |

≥420 |

| 0.36 |

Tungsten Wire Rope |

1X7 |

≥265 |

| 0.33 |

Tungsten Wire Rope |

1X7 |

≥225 |

| 0.30 |

Tungsten Wire Rope |

1X7 |

≥205 |

| 0.28 |

Tungsten Wire Rope |

1X7 |

≥180 |

| 0.24 |

Tungsten Wire Rope |

1X7 |

≥155 |

| 0.24 |

Tungsten Wire Rope |

1X7 |

≥110 |

IV. Major Customers:

|